SEOUL, August 26 (AJP) - Researchers from the Korea Advanced Institute of Science & Technology (KAIST) have developed an artificial intelligence system that can keep detecting defective products in smart factories even when machines are replaced or production conditions change. The breakthrough solves a long-standing weakness in factory AI systems, which often fail when equipment or operating environments are altered.

The research team, led by Professor Lee Jae-gil of KAIST's School of Computing, announced the results on August 26. The new method improves accuracy by up to 9.42 percent compared with existing approaches. The findings were presented earlier this month at KDD 2025, the world's leading academic conference on artificial intelligence and data science.

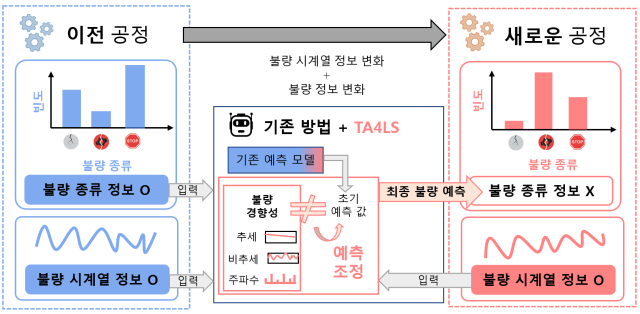

In modern smart factories, sensors collect streams of data on things like machine vibration, temperature, pressure, or power use. This kind of information is called time-series data because it is recorded continuously over time. AI models trained on this data can spot signs of faulty production early. However, if a company switches to new machines or changes a production line, the data patterns change, and the AI accuracy drops sharply. In some cases, even the types of defects change. For example, in semiconductor manufacturing, one line might mostly produce circular defects, while another line may show more scratch defects.

Lee’s team tackled this problem by developing time-series domain adaptation technology. In simple terms, this allows an AI model trained in one environment to keep working in another environment without being retrained. Normally, retraining requires a huge amount of time and cost because humans must label thousands of examples of defective and non-defective products. The new method avoids that step.

The system works by breaking down sensor data into three parts: trend, which shows long-term changes like gradual heating; detrend, which shows short-term fluctuations such as sudden machine shakes; and frequency, which shows repeating cycles like the rotation of a motor. Looking at all three together allows the AI to understand whether changes in the data are normal or signs of trouble, much like a doctor checking pulse, temperature, and blood pressure together when diagnosing a patient.

The researchers call their approach "TA4LS," short for Time-series domain Adaptation for mitigating Label Shifts. A label in AI means the category attached to data, such as whether a product is good or defective. A label shift happens when the balance of categories changes. For example, one type of defect might become much more common than another after equipment is changed. TA4LS automatically compares the predictions made by the old AI model with the patterns in the new data and adjusts the results to match the new conditions.

A major advantage of the system is that it works like a plug-in module. Companies do not need to rebuild their AI from scratch. They can simply add this method to their existing systems, making it cheaper and easier to maintain.

In experiments using four benchmark datasets that represent different kinds of sensor changes, the KAIST team achieved up to 9.42 percent higher accuracy than existing methods. The system was especially effective when defect patterns shifted significantly, proving that it could adapt itself without extra training.

"This technology addresses one of the biggest obstacles to applying AI in manufacturing, which is the need to retrain models every time processes change," said Lee Jae-gil. "Once put into practice, it can reduce operating costs and improve defect detection rates, greatly supporting the wider adoption of smart factories."

The study's first author is doctoral student Na Ji-hye. Doctoral student Nam Young-eun and LG AI researcher Kang Jun-hyuk also contributed. The work was supported by the Ministry of Science and ICT and the Institute of Information and Communications Technology Planning and Evaluation as part of South Korea’s software computing technology development program.

The researchers believe the technology could also be used in other fields that rely on sensor data. In healthcare, it could ensure that wearable devices provide accurate monitoring even if the device model changes. In smart cities, it could keep services stable when sensors are replaced or when environments shift. By lowering the costs of maintaining AI, the approach could make adoption easier across many industries.

Copyright ⓒ Aju Press All rights reserved.