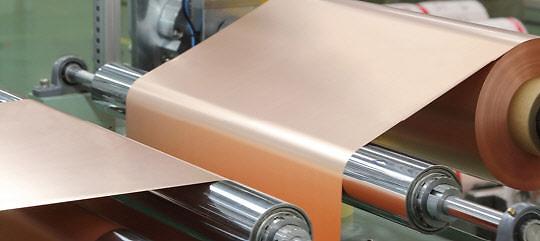

[Courtesy of Iljin Materials]

Iljin said the tensile strength of its ISS-T9 ISS-T9 Elecfoil, a thin copper foil used as a core material for rechargeable batteries, stands at 90kgf/㎟, the highest of its kind. ISS-T9 has secured three times the tensile strength of ordinary electric foil while maintaining the high elongation of previously released products.

"ISS-T9 is a necessary material for battery development that can increase silicon content and improve process defects that occur when manufacturing high-capacity, high-power batteries," CEO Yang Jeom-sik said in a statement on September 15. "This product development is significant in that it has increased national competitiveness in the material field for secondary batteries and preoccupied the future material market."

Iljin has vowed to differentiate its domestic plant into high-value products for semiconductors, with its Malaysian plant specializing in Elecfoil. In June 2022, Iljin clinched a long-term order worth 8.52 trillion won ($6.1 billion) from Samsung SDI, a battery maker in South Korea, to provide Elecfoil by the end of 2030. The supply of Elecfoil may change from 55 to 80 percent depending on Samsung SDI's total usage, leading to the fluctuation in contract money.

Samsung SDI has disclosed an investment of over $2.5 billion to build its joint venture battery plant with Stellantis N.V., an automotive manufacturing company headquartered in Amsterdam. The plant in Kokomo, Indiana, would have an initial annual production capacity of 23 gigawatts hours (GWh) that can go up to 33 GWh. Production is to begin in the first quarter of 2025.

Samsung SDI has secured a competitive advantage in terms of performance and cost by producing prismatic batteries. Prismatic cells are encased in aluminum or steel for stability and satisfy the demand for thinner sizes. Wrapped in packages, prismatic cells make optimal use of space and allow flexible design but they can be more expensive to manufacture and have a shorter cycle life than cylindrical design.

Copyright ⓒ Aju Press All rights reserved.