[Courtesy of SK E&S]

SEOUL -- SK E&S, an energy company affiliated with South Korea's SK Group, will invest $25 million in Monolith Materials, an American turquoise hydrogen company. The investment is aimed at seeking new business opportunities in the domestic market by combining Monolith's technology with SK E&S' hydrogen business capabilities.

Turquoise hydrogen sits somewhat between blue and green hydrogen and uses methane as a feedstock, but the process is driven by heat produced with electricity instead of fossil fuels. Methane pyrolysis produces hydrogen and a solid carbon material called "carbon black" that can be used in other applications.

SK Group regards turquoise hydrogen as a strategic alternative to an energy shift from blue hydrogen to green hydrogen. Blue hydrogen is produced by applying carbon capture and storage to reduce CO2 emissions. Green hydrogen can be produced through electrolysis to split water and release only hydrogen and oxygen.

"Turquoise hydrogen has the advantage of not generating carbon dioxide during production. We will focus on optimizing the portfolio of hydrogen businesses by applying our blue and green hydrogen business capabilities to turquoise hydrogen," Kwon Hyung-kyun, head of SK E&S' hydrogen business development unit, said in a statement on July 18.

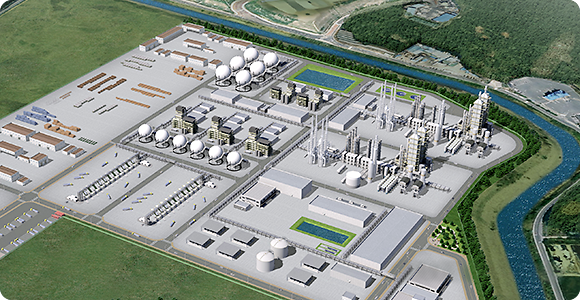

SK E&S aims to produce 30,000 tons of liquefied hydrogen annually from the end of 2023 through a hydrogen liquefaction plant under construction in the western port city of Incheon. A blue hydrogen plant capable of producing 250,000 tons of hydrogen every year from 2025 will be built in the southwestern coastal city of Boryeong.

Monolith has signed a $1 billion growth loan agreement with the U.S. Department of Energy and carbon black sales agreements with tire companies including Good Year.

In October 2021, SK Inc., an investment-oriented holding company of SK Group, agreed to set up a joint venture and cooperate in carbon-free solid carbon material businesses. Solid carbon or carbon black is used as additives that enhance products' physical, electrical and optical properties. Natural and synthetic elastomers are blended with carbon black and other materials to produce vulcanized rubber (hardened rubber) products.

Copyright ⓒ Aju Press All rights reserved.