[Courtesy of POSCO]

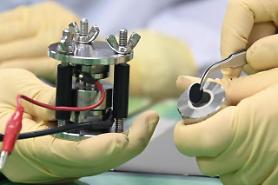

The solid electrolyte factory in Yangsan, some 290 kilometers (180 miles) southeast of Seoul, will be jointly run by POSCO Holdings and Jeong Kwang, a domestic solid electrolyte material manufacturer, which set up a joint venture named Posco JK Solid Solution in January 2022.

"Solid electrolytes are POSCO's representative future material business," Yoo Byeong-og, head of POSCO Holdings' eco-friendly future materials team, said in a statement on October 28. "Based on the completion of Posco JK Solid Solution's plant, we will conduct certification for global battery and finished car companies and expand production to thousands of tons to preoccupy the next-generation secondary battery material market."

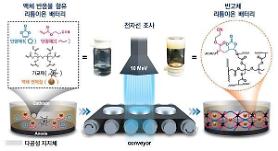

South Korean companies strive hard to gain a competitive edge in a global battery war by releasing efficient next-generation products with affordable manufacturing costs, such as all-solid-state batteries which are seen as a next-generation power source for electric vehicles. Solid electrolytes are nonflammable and more stable. They can have a higher energy density than lithium-ion batteries.

The steel group regards battery materials as its next growth engine. Group chairman Choi Jeong-woo has presented a goal to invest 25 trillion won ($10 billion) by 2030 and establish a system capable of producing 420,000 tons of cathodes and 260,000 tons of anodes.

In May 2022, POSCO Holdings made a strategic equity investment in Taiwan's solid-state battery developer Prologium Technology to cooperate in the production of all-solid-state battery electrolytes. They will jointly develop cathode materials for solid solid-state batteries, silicon anode materials, and solid electrolytes and establish a global supply system.

Two months later, POSCO Holdings acquired 100 percent of Tera Technos, a domestic silicon anode startup with a high-temperature liquid production technology with excellent heat transfer. Commercial production is to begin in the first half of 2024.

Graphite anodes are widely used for lithium-ion batteries, but researchers have tried to find a better solution because structural deformation occurs in graphite when charging and discharging are repeated, leading to a shorter life of batteries. Silicon is a promising anode material and shows higher energy density than graphite. Researchers have tried to acquire technology for the production of a composite anode material with low silicon content.

Copyright ⓒ Aju Press All rights reserved.