SEOUL, September 02 (AJP) - The Ulsan National Institute of Science and Technology said Tuesday it had developed an artificial intelligence-based inspection system that can detect microscopic assembly defects in less than three seconds, a breakthrough that could speed up manufacturing and cut costs across multiple industries.

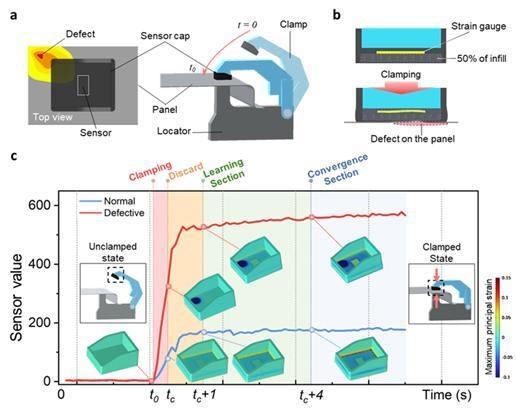

The system, designed by a team led by Professor Jung Im-doo of the university’s Department of Mechanical Engineering, uses a “smart jig” — a fixture that holds parts in place during assembly — fitted with soft, 3D-printed sensor caps.

When components are clamped down, the caps deform slightly to reflect the surface profile. AI algorithms then analyze those patterns to spot irregularities the moment parts are secured.

Defects often occur when component surfaces do not align properly, weakening joints and lowering product quality.

Traditional inspection methods can take more than 10 minutes per part. The new system reduces that to just 2.79 seconds, enabling full inspection without slowing automated production lines, the researchers said.

The system visualizes results in heat maps, allowing operators to quickly identify both the location and severity of flaws. It is capable of detecting defects as small as a few hundred micrometers, or millionths of a meter.

Professor Jung said the technology could be applied in sectors ranging from electric vehicles and home appliances to semiconductors and aerospace.

“We expect annual cost savings in the hundreds of millions of won through reduced inspection staff and time, improved quality reliability, and minimized defects,” he said in a statement.

Copyright ⓒ Aju Press All rights reserved.