SEOUL, September 10 (AJP) - Cars glide down the assembly line with the practiced rhythm of human workers moving in unison in ordinary automotive plants. But if a new vision of the future proves correct, those workers may soon be replaced by machines that look uncannily like them.

Humanoid robots — once confined to science fiction and corporate stage shows — are being recast as the next frontier of industrial labor.

And according to a recent analysis by Samsung Securities, their widespread adoption could do more than reshape factory floors. It could cut the cost of building cars so dramatically that sticker prices fall by half.

The math, at least on paper, is compelling. A Hyundai Motor plant in Korea pays an average of $38 per hour in labor costs, already a fraction of what Detroit automakers are on track to spend by 2027.

But Tesla’s Optimus robot, used as a benchmark in the Samsung study, could operate at just $14 per hour if purchased for $100,000 and run around the clock. If mass production slashes robot prices to $30,000, as some expect, the figure plunges to $5 per hour — cheaper than labor in China, the global capital of low-cost manufacturing.

For automakers, the potential payoff is enormous. Hyundai’s current two-shift system tops out at 310,000 cars a year. Robots never sleep, and with 24-hour operations, annual output could climb to 520,000 vehicles, a 60 percent jump. Analysts say such efficiency could drive down plant costs from nearly 80 percent to the low 40s, opening the door to cars priced at levels unimaginable today.

But reality is still far messier than the spreadsheets suggest. Robots tire more quickly than humans — their batteries last only about two hours — and wear out faster too, with critical components needing replacement within a year.

“They are best suited right now for simple, repetitive tasks,” Yoo Beom-jae, a senior researcher at the Korea Institute of Science and Technology, told AJP. “Substantial development is still needed before they can take on full production roles.”

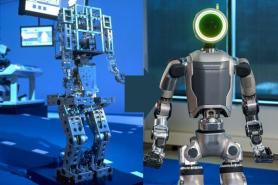

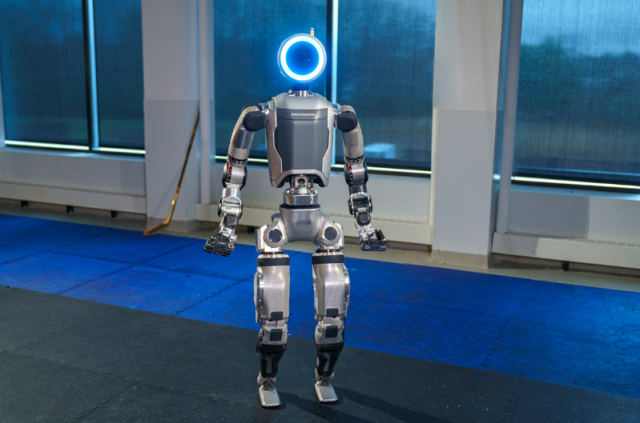

BMW is putting robots from the California start-up Figure to work in South Carolina. Mercedes-Benz is using Apptronik’s Apollo models in Europe. BYD, the Chinese electric vehicle giant, has already deployed 500 humanoid robots on its factory floors. Hyundai, not to be left behind, plans to roll out Boston Dynamics’ Atlas robots at its new Georgia plant later this year.

The changes underway may reach far beyond cars.

Lim Eun-young, who led the Samsung Securities study, believes humanoid robots could help catalyze an economic transformation. “If vehicles become both cheap and smart,” she said, “transportation becomes more efficient, traffic is better organized, and the number of cars in cities actually decreases. We could reclaim parking lots and free up enormous amounts of space.”

The stakes are high, and national competitiveness may be on the line.

“This is not a change Korea can ignore,” Lim warned. “The United States and China are already racing ahead. Without active government support in building data centers and power grids, Korea risks falling behind and becoming dependent on others’ technology.”

Copyright ⓒ Aju Press All rights reserved.