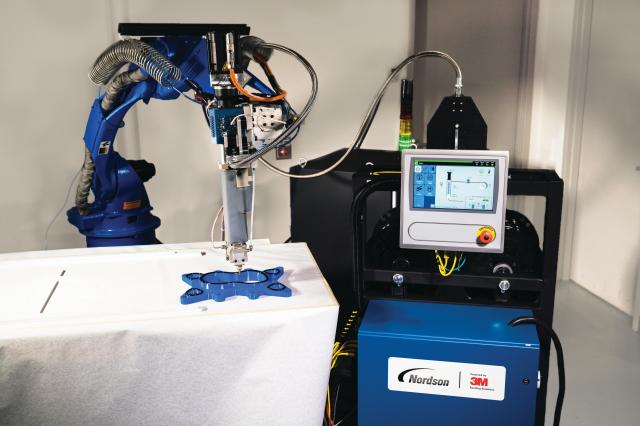

HWASUNG, December 09 (AJP) - A multi-axis industrial robot sweeps deliberately across a component panel, its joints pivoting with an almost animal-like fluidity.

From a needle-fine nozzle, it extrudes a glossy black ribbon of liquid-form tape that catches the overhead lights before settling into a perfect line.

As the machine arcs over curved ridges and dips into semi-circular edges — surfaces that typically force human technicians to slow their breathing and reset their hands — bundles of cables trail from its arm like tendrils.

Each pass lands with identical precision, as though the robot were tracing an invisible blueprint only it can see.

Inside a restricted-access lab at 3M Korea’s research center in Hwaseong, the demonstration feels part workshop, part choreography.

A 3M engineer stands at a console, tuning parameters and occasionally nudging the robot’s movement.

“With flexible automation, the robot is now dispensing tape more precisely than a human can,” he said, watching the tape settle into flawless contours.

The system — branded internally as RoboTape™ System— is built for unbroken consistency and speed, traits Korean manufacturers increasingly regard not as advantages but as survival requirements.

U.S.-based materials giant 3M is now leaning on Korea’s demanding industrial environment to pressure-test and refine its next-generation automation technologies before deploying them globally.

At a technology briefing Monday, company executives underscored how Korean manufacturers — known for unforgiving specifications, rapid development cycles and millimeter-level quality thresholds — are directly influencing the evolution of automated bonding, sealing and dispensing systems across appliances, displays and electric vehicles.

“Korean customers require extremely detailed performance data before finalizing their product designs,” said Choi Bokyung, a senior application engineer at 3M Korea. “To complete their modeling, they need reliable simulation data for each material going into a component. We share that data actively so customers can raise the overall completeness of their designs.”

That data-heavy collaboration has intensified as manufacturers race to automate tasks once handled manually, driven by rising labor costs, worker shortages and increasingly complex internal product architectures. According to 3M, robotic tape and adhesive systems not only reduce reliance on manual work but deliver uniformity that human operators cannot consistently match.

Choi said labor costs — in a country known for powerful unions and high wages — are one of the strongest incentives behind automation.

“When production depends heavily on manual work, quality can vary dramatically between operators,” she said. “Automation makes sure end users receive the same level of quality every time.”

But the business case hinges on scale. Chung Sehoon, bonding project specialist leader at 3M Korea, noted that automation only becomes cost-effective when it replaces larger teams.

“In our experience, automation doesn’t always make sense when a line has just two or three workers,” he said. “In those cases, costs may even rise. But when you’re running lines that need 10 or 20 workers, the labor savings far outweigh the automation investment.”

As product designs grow more intricate, automated tape systems are entering areas once off-limits to manual work: curved appliance housings, the maze-like wiring harnesses inside refrigerators, large-format displays, and irregular surfaces beneath what appear to be flat exteriors.

At the heart of 3M’s strategy is the goal of turning automated tape and adhesive solutions into a core platform technology. The company showcased two approaches: extrusion-based systems that dispense tape directly from specialized cartridges, and robotic tape systems co-developed with Canadian equipment maker Innovative Automation.

“Not every tape can be automated,” Choi noted. “The material and equipment must be designed together — which is why we partner with high-quality equipment firms to ensure stable performance.”

One of the clearest testing grounds is the automotive sector, where electrification has rewritten bonding requirements. Battery packs must be tightly sealed against water and contaminants yet be removable for repairs — a dual demand traditional adhesives struggle to meet.

“That’s why we developed elastic sealants that preserve airtight performance while remaining removable when necessary,” said Joo Hyung Suk, director overseeing 3M’s automotive business. He said 3M’s elastic battery sealant is already used by major Korean automakers and overseas manufacturers. The material stays elastic for years, preventing moisture intrusion while allowing service teams to reopen the pack without damage.

Automation is what makes these solutions viable at scale, Joo emphasized. “Automation is no longer optional. Without automated processes, achieving both price competitiveness and consistent quality is impossible.”

3M also highlighted high-strength structural adhesives — capable of bonding chassis and body components with strength approaching welding — but without the heat-induced distortion of traditional welding processes. Because the adhesives cure at room temperature, they lower energy consumption and are more compatible with lightweight materials such as aluminum and carbon-fiber composites.

These decisions — from heat tolerance to load-bearing needs — are set through intensive collaboration with automakers, Joo said.

Across the briefing, executives repeatedly pointed to Korea’s role as a fast-moving, high-specification market that has become a global testbed for 3M. Feedback from Korean customers is relayed to global R&D teams almost instantly, accelerating development cycles well beyond what is possible elsewhere.

With automation demand rising across sectors, 3M expects its automated tape and adhesive systems not only to support Korea’s industrial competitiveness but also to anchor its next phase of global expansion.

Copyright ⓒ Aju Press All rights reserved.