SEOUL, December 22 (AJP) - Professor Yoo Seung-hwa and his research team at the Korea Advanced Institute of Science and Technology (KAIST) have developed an artificial intelligence system that can automatically manage factory machines and guide workers. The technology was created to help factories maintain production quality as experienced experts retire and more foreign workers enter the workforce, potentially creating language barriers on the factory floor.

Most plastic items used today are made through a process called injection molding. This involves melting plastic and pouring it into a mold to create many identical parts at once. However, the process is very sensitive. Small changes in room temperature or humidity can cause the plastic parts to come out with defects. For a long time, factories have relied on the "gut feeling" of highly experienced workers to manually adjust the machine settings when the weather or conditions change.

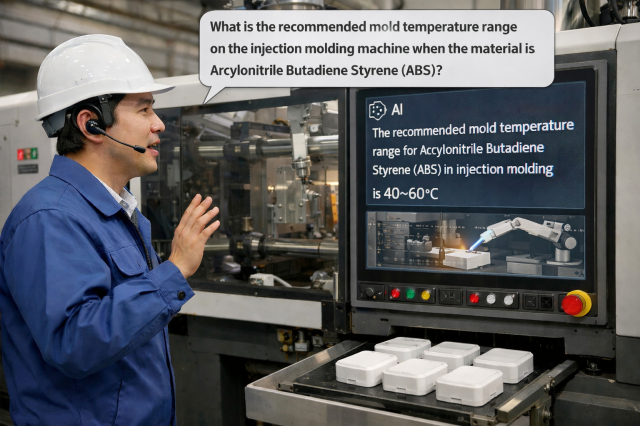

The research team at the KAIST Department of Mechanical Engineering and the Inno-Core PRISM-AI Center created two main tools to solve this problem. The first is a generative AI engine that acts like an expert's brain. It looks at the factory’s current environment, such as the humidity level, and automatically calculates the perfect pressure and speed for the machine. The second tool is a digital assistant called "IM-Chat." This chatbot uses a large language model to answer questions from workers in plain language.

When a worker asks the chatbot a question, such as "What is the best pressure when the humidity is 43.5 percent?", the system does not just give a random answer. It automatically triggers the AI engine to do the math and then provides the worker with the exact settings along with an explanation from the factory's technical manuals. Because the system supports multiple languages, it allows newer or foreign workers to make the same high-level decisions as a human expert who has worked in the factory for decades.

During testing, the AI proved to be much more reliable than older technology. Previous AI models used for this work often had error rates between 23 and 44 percent. The new system developed by the KAIST team reduced that error rate to just 1.63 percent. In real-world factory tests, the machine settings suggested by the AI successfully produced high-quality parts without any human help.

"This is a case where we solved the core problems of manufacturing by using data-based AI," said Professor Yoo Seung-hwa. "By combining an AI that can optimize the factory process on its own with a system that can explain that knowledge to anyone, we hope to make many different types of industries more independent and automated."

The researchers believe this technology can be used for more than just plastic. It could eventually be applied to making batteries, 3D printing, and even medicine. The project was a collaboration between several researchers, including doctoral students Kim Jun-young, Kim Hee-gyu, and Lee Jun-hyeong, who served as co-first authors. The work was supported by the Ministry of Science and ICT, the Ministry of SMEs and Startups, and the Ministry of Trade, Industry and Energy.

[Paper information]

Journal: Journal of Manufacturing Systems (JCR 1/69, IF 14.2) Title: Development of an Injection Molding Production Condition Inference System Based on Diffusion Model DOI: https://doi.org/10.1016/j.jmsy.2025.01.008

Journal: Journal of Manufacturing Systems (JCR 1/69, IF 14.2) Title: IM-Chat: A multi-agent LLM framework integrating tool-calling and diffusion modeling for knowledge transfer in injection molding industry DOI: https://doi.org/10.1016/j.jmsy.2025.11.007

Copyright ⓒ Aju Press All rights reserved.