SEOUL, February 03 (AJP) - Humanoid robots are designed for work that is tedious, costly or dangerous for humans. To meet that purpose, their architecture does not merely imitate the human body — it often stretches beyond it, with joints capable of rotating 360 degrees to exceed natural human limits.

Boston Dynamics captured the innovative mind from South Korea's DRC-HUBO robot — first showcased at the DARPA Robotics Challenge — into its Atlas humanoid. The machine features mechanical joints with 56 degrees of freedom, allowing a full range of motion that far surpasses human flexibility.

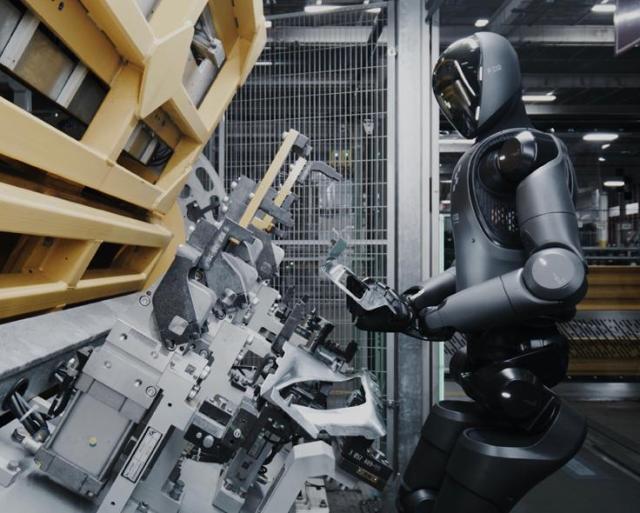

As if to underscore its machine origins, Atlas's ocular head glows with light.

The supply chain gap

Beneath the gleaming promise of Korea's humanoid push, however, lies a structural vulnerability.

A Jan. 26 report by the Korea International Trade Association estimates South Korea's localization rate for robot components at around 40 percent, underscoring the industry's heavy reliance on foreign parts.

Japan, by contrast, has internalized rare-earth processing and core component production, exporting more than 70 percent of its robot output. Korea — despite leading the world in robot density at 1,012 units per 10,000 workers — exports just 28.8 percent.

As Hyundai Motor Group moves to deploy Atlas, many of the actuators and sensors powering the machines may still bear Japanese and Chinese stamps. Building robots, it turns out, is not the same as building an industry.

The price of progress

Analysts say Atlas will not come cheap.

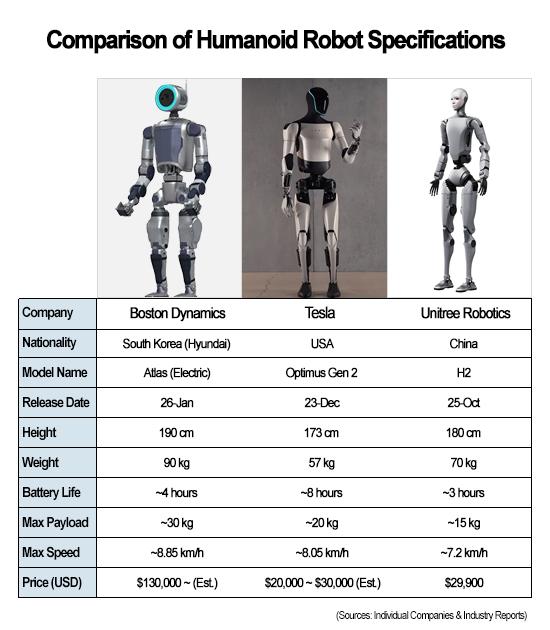

Boston Dynamics has said pricing will be based on "investment recovery within two years," effectively placing the robot below roughly 200 million won ($130,000) — nearly equivalent to the labor cost of two U.S. auto workers earning $80,000 annually over that period.

The figure is steep compared with rivals. Tesla has promised its Optimus humanoid for $20,000 to $30,000, while China's Unitree offers its H2 model starting at $29,900.

Hyundai is betting that Atlas's superior specifications justify the premium: 56 degrees of freedom, a lifting capacity of 90 kilograms, and the ability to swap its own batteries — capabilities cheaper competitors have yet to match.

Price alone, however, does not determine whether robots can replace workers. Speed and precision matter just as much.

For now, humanoid deployments remain concentrated in logistics, simple handling and repetitive tasks — not high-precision assembly or work requiring human-level dexterity.

Fine-motor control and tactile sensitivity remain in early stages, with significant gaps still evident, according to Bain & Company.

So why pursue humanoids when industrial robots already dominate factory floors?

"These bipedal robots can replace humans directly," said Kim Dong-wan, a project director at the Korea Planning & Evaluation Institute of Industrial Technology.

"Most mobile robots rely on wheels, which are poorly suited to uneven terrain such as steel plants. Humanoids can walk over obstacles, press buttons — essentially performing the same tasks as human workers."

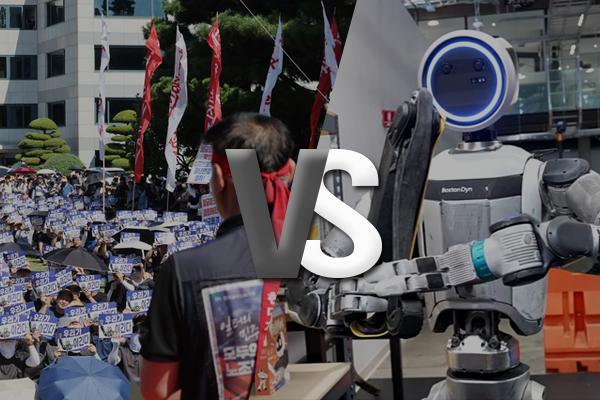

The announcement of Atlas roaming factory grounds sent Hyundai's stock to an all-time high of 590,000 won on Jan. 22 — but also triggered resistance from an unexpected quarter: its own workers.

That same day, Hyundai Motor's labor union declared that "not a single robot" would enter workplaces without labor-management agreement, warning of potential "employment shocks."

"The introduction of AI robots aimed at cutting labor costs is becoming visible," the union said. "If you want to destroy labor-management relations, we will show you how it ends."

The tidal wave approaches

President Lee Jae Myung weighed in on Jan. 29, invoking the industrial upheavals of two centuries ago.

"You cannot dodge an oncoming cart," Lee told senior aides. "If this world is coming anyway, we must prepare and brace for it."

Lee compared the union's stance to the Luddite movement of early 19th-century Britain, when workers destroyed machines they feared would render them obsolete.

"It's probably not serious — more a negotiating tactic," he said. "But ultimately, we need to adapt quickly."

Both major umbrella unions told AJP that Hyundai's labor group may have gone too far in declaring opposition to "a single robot."

"Robot integration into workplaces is nearly irreversible," said a spokesperson for the Federation of Korean Trade Unions. "Government, companies and labor all need to discuss how to coexist."

The Korean Confederation of Trade Unions echoed that view but stressed concerns over unequal distribution of the benefits of humanoid technology.

"This is a transitional moment," it said. "Shorter working hours and improved welfare are possible. But humanoids must benefit society broadly — not simply enrich executives while workers are laid off."

The human factor

Yet the union's statement reflects a deeper anxiety: the surge in Hyundai's stock — fueled by investor expectations of reduced labor costs, though now slightly dampened — highlights precisely the threat workers perceive.

"We estimate it will take many years before humanoids meet the standards required for high-precision tasks," Kim said. "Korea is pushing hard for that transition, but we cannot promise when bipedal robots will perform truly difficult work."

The question is no longer whether humanoids will work alongside humans, but how soon — and on whose terms.

The robots that stumbled at the DARPA challenge a decade ago are now walking factory floors. The workers who once cheered their failures now face them across the assembly line.

Copyright ⓒ Aju Press All rights reserved.