The groundbreaking ceremony for the facility — billed as an “insect smart factory” — was held Wednesday in the city of Chuncheon, with Gangwon Province Governor Kim Jin-tae and LG CNS Executive Vice President Kim Hong-keun in attendance.

The factory will use advanced automation and AI-driven systems to breed, monitor, and harvest insects such as mealworms at industrial scale.

By deploying its proprietary manufacturing automation platform, LG CNS aims to manage the entire production process — from breeding to quality control — through a unified, data-driven control system.

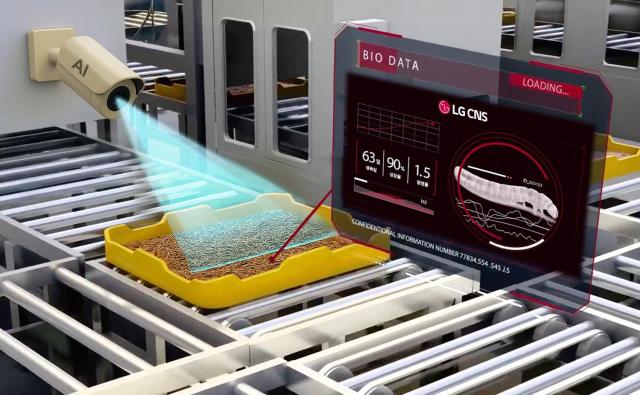

At the core of the factory’s operations is an AI system designed to monitor insect growth stages in real time.

The technology analyzes movement patterns and color variations to detect abnormalities or disease, identifying substandard or dead specimens before they can contaminate batches. The system is intended to solve a persistent challenge in traditional insect farming, where manual sorting is both labor-intensive and unreliable at scale.

“LG CNS will deliver fundamentally differentiated value to customers by combining our automation innovation with the emerging insect industry,” said Kim, the company’s executive vice president.

The Chuncheon facility is expected to produce roughly 700 tons of mealworms annually by the end of the year. The insects are widely used in animal feed, protein supplements, and biodegradable materials — key components in efforts to create more sustainable food and resource systems.

While insect farming has long been touted as a potential solution to climate and food security issues, scaling production has proven difficult. LG CNS’s entry into the sector reflects a broader push among Korean tech firms to apply AI and automation to ecological and agricultural challenges.

Copyright ⓒ Aju Press All rights reserved.