Journalist

박세진

-

S. Korean startups urged to rethink global scale-up as a process of repetition and trust LAS VEGAS, January 08 (AJP) - “Global-ready is not about translating slides into English,” one Silicon Valley investor said. “It is about proving demand, again and again.” That message shaped discussions on Korean startups’ global expansion at the AJP Global Innovation Growth Summit 2026 (GIGS 2026), held on Jan. 7 (local time) at the Planet Hollywood Hotel in Las Vegas. Investors stressed that success in overseas markets is determined less by technology or vision than by execution, validation, and credibility built over time. The discussion session brought together Silicon Valley investors to explain how global capital evaluates early-stage companies in practice. Tomasz Kolodziejczak, former head of innovation initiatives at Samsung Research, said Korea has no shortage of strong technical talent, but that advantage often weakens outside the domestic market. Global investors, he noted, place greater weight on founders’ execution and decision-making than on sector or technology labels. Business models that work at home frequently need to be abandoned and rebuilt from scratch to fit overseas markets. A sector-level perspective came from healthcare investor Cheryl Campos, former head of the Republic Venture Growth Partnership, who pointed to femtech and silver tech as areas where large populations remain underserved. The challenge, she suggested, is rarely technological. Instead, it lies in weak problem definition and a limited understanding of real customer needs. That focus on fundamentals was reinforced by Mitchell Weinstock, a venture partner at HP Tech Ventures. Being global-ready, he warned, is often misunderstood. Translating pitch materials into English does little on its own. What matters is repeated demand validation, built through sustained customer engagement and constant verification. Investor-founder dynamics also emerged as a key theme. Campos cautioned against approaching venture capital firms from a position of weakness, arguing that startups should present opportunities rather than requests for funding. Overstated market claims or selective disclosure, participants agreed, undermine trust and damage long-term credibility. Across the session, investors consistently framed global expansion not as a single leap driven by ambition, but as a cumulative process shaped by repetition, disciplined execution, and trust earned over time. 2026-01-08 18:45:33

S. Korean startups urged to rethink global scale-up as a process of repetition and trust LAS VEGAS, January 08 (AJP) - “Global-ready is not about translating slides into English,” one Silicon Valley investor said. “It is about proving demand, again and again.” That message shaped discussions on Korean startups’ global expansion at the AJP Global Innovation Growth Summit 2026 (GIGS 2026), held on Jan. 7 (local time) at the Planet Hollywood Hotel in Las Vegas. Investors stressed that success in overseas markets is determined less by technology or vision than by execution, validation, and credibility built over time. The discussion session brought together Silicon Valley investors to explain how global capital evaluates early-stage companies in practice. Tomasz Kolodziejczak, former head of innovation initiatives at Samsung Research, said Korea has no shortage of strong technical talent, but that advantage often weakens outside the domestic market. Global investors, he noted, place greater weight on founders’ execution and decision-making than on sector or technology labels. Business models that work at home frequently need to be abandoned and rebuilt from scratch to fit overseas markets. A sector-level perspective came from healthcare investor Cheryl Campos, former head of the Republic Venture Growth Partnership, who pointed to femtech and silver tech as areas where large populations remain underserved. The challenge, she suggested, is rarely technological. Instead, it lies in weak problem definition and a limited understanding of real customer needs. That focus on fundamentals was reinforced by Mitchell Weinstock, a venture partner at HP Tech Ventures. Being global-ready, he warned, is often misunderstood. Translating pitch materials into English does little on its own. What matters is repeated demand validation, built through sustained customer engagement and constant verification. Investor-founder dynamics also emerged as a key theme. Campos cautioned against approaching venture capital firms from a position of weakness, arguing that startups should present opportunities rather than requests for funding. Overstated market claims or selective disclosure, participants agreed, undermine trust and damage long-term credibility. Across the session, investors consistently framed global expansion not as a single leap driven by ambition, but as a cumulative process shaped by repetition, disciplined execution, and trust earned over time. 2026-01-08 18:45:33 -

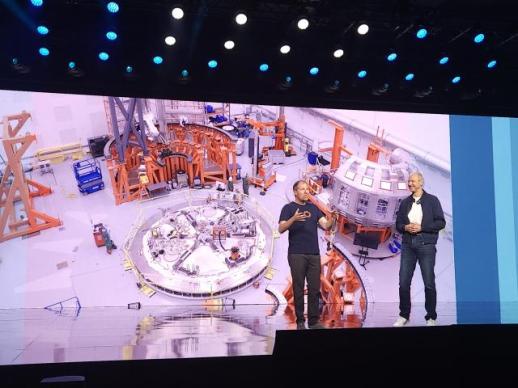

Siemens maps AI-led industrial shift at CES, with fusion reactors highlighting digital twin strategy LAS VEGAS (AJP) - At CES 2026, Siemens outlined a vision for an AI-driven restructuring of global industry, arguing that artificial intelligence is moving beyond software applications to become a foundational element of physical systems across manufacturing, logistics, energy, and infrastructure. At the center of that strategy is digital twin technology, which the company presented as the key mechanism for applying AI safely and reliably in the real world. Siemens framed digital twins not as visualization tools but as operational replicas of physical systems. By integrating design data, operating conditions, physical laws, and real-time sensor information, digital twins allow companies to test and validate thousands of scenarios before assets are built or deployed. According to Siemens, this capability is critical in industries where errors carry high costs or safety risks, and where traditional trial-and-error approaches are impractical. Roland Busch, president and CEO of Siemens, emphasized those constraints during his keynote on Jan. 6 at the Venetian Hotel in Las Vegas. “In the industrial world, AI hallucinations are not acceptable,” Busch said. “AI that enters physical systems is no longer just a feature. It becomes a force with direct real-world impact.” Reliability and safety, he added, are prerequisites for deploying AI at industrial scale, making digital twins a necessary foundation rather than an optional enhancement. The company used nuclear fusion energy as its most prominent example of that approach in practice. Siemens highlighted its collaboration with Commonwealth Fusion Systems, a U.S.-based fusion startup, to demonstrate how digital twins can accelerate development in fields defined by extreme complexity and risk. Fusion reactors require precise coordination among magnets, cooling systems, and power controls, where even small design flaws can have serious consequences. Busch said such systems leave no room for real-world experimentation. “In these environments, trial and error in the physical world is not an option,” he said. Every design choice and operating condition must be validated in a digital twin, where physical behavior can be simulated repeatedly before any hardware is built. Siemens argued that this process shortens research and development timelines while reducing the likelihood of costly or dangerous failures. Siemens positioned the fusion work as a template rather than a one-off case. The same digital twin framework, the company said, can be applied to factories, logistics centers, and power grids. By combining virtual replicas of these systems with AI, operators can anticipate disruptions, optimize performance, and adjust operations in real time. Busch described this shift as a move away from reacting to problems after they occur toward designing systems that act proactively. Partnerships with major technology firms were presented as critical to making that model work at scale. Siemens pointed to its collaborations with NVIDIA and Microsoft as efforts to link AI-accelerated computing, simulation technologies, and industrial AI copilots into a single workflow spanning design, manufacturing, and operations. The company also showcased hands-free, smart-glasses-based guidance for shop-floor workers, positioning it as a way to improve safety and productivity while narrowing skill gaps. At CES 2026, Siemens focused less on individual product announcements than on defining how AI can be embedded into physical systems without compromising safety or reliability. By using fusion reactors as a proving ground for digital twin technology, the company sought to show how AI-driven simulation can reduce risk and compress development cycles in the most demanding industrial environments, before extending that same logic across manufacturing, logistics, energy, and infrastructure. 2026-01-07 15:44:38

Siemens maps AI-led industrial shift at CES, with fusion reactors highlighting digital twin strategy LAS VEGAS (AJP) - At CES 2026, Siemens outlined a vision for an AI-driven restructuring of global industry, arguing that artificial intelligence is moving beyond software applications to become a foundational element of physical systems across manufacturing, logistics, energy, and infrastructure. At the center of that strategy is digital twin technology, which the company presented as the key mechanism for applying AI safely and reliably in the real world. Siemens framed digital twins not as visualization tools but as operational replicas of physical systems. By integrating design data, operating conditions, physical laws, and real-time sensor information, digital twins allow companies to test and validate thousands of scenarios before assets are built or deployed. According to Siemens, this capability is critical in industries where errors carry high costs or safety risks, and where traditional trial-and-error approaches are impractical. Roland Busch, president and CEO of Siemens, emphasized those constraints during his keynote on Jan. 6 at the Venetian Hotel in Las Vegas. “In the industrial world, AI hallucinations are not acceptable,” Busch said. “AI that enters physical systems is no longer just a feature. It becomes a force with direct real-world impact.” Reliability and safety, he added, are prerequisites for deploying AI at industrial scale, making digital twins a necessary foundation rather than an optional enhancement. The company used nuclear fusion energy as its most prominent example of that approach in practice. Siemens highlighted its collaboration with Commonwealth Fusion Systems, a U.S.-based fusion startup, to demonstrate how digital twins can accelerate development in fields defined by extreme complexity and risk. Fusion reactors require precise coordination among magnets, cooling systems, and power controls, where even small design flaws can have serious consequences. Busch said such systems leave no room for real-world experimentation. “In these environments, trial and error in the physical world is not an option,” he said. Every design choice and operating condition must be validated in a digital twin, where physical behavior can be simulated repeatedly before any hardware is built. Siemens argued that this process shortens research and development timelines while reducing the likelihood of costly or dangerous failures. Siemens positioned the fusion work as a template rather than a one-off case. The same digital twin framework, the company said, can be applied to factories, logistics centers, and power grids. By combining virtual replicas of these systems with AI, operators can anticipate disruptions, optimize performance, and adjust operations in real time. Busch described this shift as a move away from reacting to problems after they occur toward designing systems that act proactively. Partnerships with major technology firms were presented as critical to making that model work at scale. Siemens pointed to its collaborations with NVIDIA and Microsoft as efforts to link AI-accelerated computing, simulation technologies, and industrial AI copilots into a single workflow spanning design, manufacturing, and operations. The company also showcased hands-free, smart-glasses-based guidance for shop-floor workers, positioning it as a way to improve safety and productivity while narrowing skill gaps. At CES 2026, Siemens focused less on individual product announcements than on defining how AI can be embedded into physical systems without compromising safety or reliability. By using fusion reactors as a proving ground for digital twin technology, the company sought to show how AI-driven simulation can reduce risk and compress development cycles in the most demanding industrial environments, before extending that same logic across manufacturing, logistics, energy, and infrastructure. 2026-01-07 15:44:38 -

CES 2026: Same day, different podiums: Nvidia and AMD faceoff in AI supercomputing LAS VEGAS — Born in the same Taiwanese city and distantly related by blood, Jensen Huang and Lisa Su took to podiums just hours apart on the same day—at different hotels along the Las Vegas Strip—and delivered rival visions for the future of artificial intelligence computing. The parallel appearances ahead of CES 2026 turned Las Vegas into a split-stage arena, with Nvidia presenting at the Fontainebleau Hotel’s BleuLive Theater and AMD countering from the Venetian. The message from both camps was unmistakable: the AI chip race has moved beyond individual processors into a full-scale contest over who defines the architecture of the modern data center. At Nvidia's press conference, Huang unveiled Vera Rubin, the company’s next-generation AI supercomputing platform, describing it as “one platform for every AI.” His argument was that AI computing has moved beyond software into the physical world—autonomous vehicles, robots, factories—where training, inference, and deployment must be engineered as a single, tightly coordinated system. “The demand for AI computing is going through the roof,” Huang said. “Rubin arrives at exactly the right moment.” Vera Rubin is a rack-scale system integrating GPUs, CPUs, networking, and data-processing components into a unified platform. Nvidia said its flagship Rubin NVL72 configuration can cut inference token costs by up to tenfold compared with its Blackwell platform and reduce by four times the number of GPUs required to train large mixture-of-experts models. Huang emphasized NVIDIA’s annual cadence of new AI architectures and its philosophy of extreme codesign across chips, networking, and software—an approach aimed at maximizing system-level efficiency as AI models grow larger and more complex. Rubin-based systems will be rolled out through partners beginning in the second half of 2026, targeting cloud providers, AI research labs, and enterprise customers running AI at massive scale. AMD counters with Helios and an open-system pitch Across the Strip, AMD responded with Helios, its next-generation AI supercomputing platform, unveiled by Su at a conference at the Venetian. Her framing focused less on vertical integration and more on flexibility as AI expands beyond digital applications into factories, healthcare, robotics, and even space systems. “Physical AI is one of the toughest challenges in technology,” Su said. “It requires systems that can understand their environment, make real-time decisions, and act with precision.” Helios is built around AMD’s Instinct MI450 series GPUs and designed as a rack-level AI system emphasizing large memory capacity, high-bandwidth HBM memory, and open interconnect technologies. AMD positioned Helios for large-scale AI training workloads where memory constraints often become a bottleneck. Su said AMD’s strategy prioritizes openness, allowing customers to expand and customize AI infrastructure without being locked into proprietary architectures. AMD plans to deploy Helios later this year through partnerships with data center operators and enterprise customers, underscoring its push to establish itself as a core platform provider in the AI ecosystem. 2026-01-06 15:06:10

CES 2026: Same day, different podiums: Nvidia and AMD faceoff in AI supercomputing LAS VEGAS — Born in the same Taiwanese city and distantly related by blood, Jensen Huang and Lisa Su took to podiums just hours apart on the same day—at different hotels along the Las Vegas Strip—and delivered rival visions for the future of artificial intelligence computing. The parallel appearances ahead of CES 2026 turned Las Vegas into a split-stage arena, with Nvidia presenting at the Fontainebleau Hotel’s BleuLive Theater and AMD countering from the Venetian. The message from both camps was unmistakable: the AI chip race has moved beyond individual processors into a full-scale contest over who defines the architecture of the modern data center. At Nvidia's press conference, Huang unveiled Vera Rubin, the company’s next-generation AI supercomputing platform, describing it as “one platform for every AI.” His argument was that AI computing has moved beyond software into the physical world—autonomous vehicles, robots, factories—where training, inference, and deployment must be engineered as a single, tightly coordinated system. “The demand for AI computing is going through the roof,” Huang said. “Rubin arrives at exactly the right moment.” Vera Rubin is a rack-scale system integrating GPUs, CPUs, networking, and data-processing components into a unified platform. Nvidia said its flagship Rubin NVL72 configuration can cut inference token costs by up to tenfold compared with its Blackwell platform and reduce by four times the number of GPUs required to train large mixture-of-experts models. Huang emphasized NVIDIA’s annual cadence of new AI architectures and its philosophy of extreme codesign across chips, networking, and software—an approach aimed at maximizing system-level efficiency as AI models grow larger and more complex. Rubin-based systems will be rolled out through partners beginning in the second half of 2026, targeting cloud providers, AI research labs, and enterprise customers running AI at massive scale. AMD counters with Helios and an open-system pitch Across the Strip, AMD responded with Helios, its next-generation AI supercomputing platform, unveiled by Su at a conference at the Venetian. Her framing focused less on vertical integration and more on flexibility as AI expands beyond digital applications into factories, healthcare, robotics, and even space systems. “Physical AI is one of the toughest challenges in technology,” Su said. “It requires systems that can understand their environment, make real-time decisions, and act with precision.” Helios is built around AMD’s Instinct MI450 series GPUs and designed as a rack-level AI system emphasizing large memory capacity, high-bandwidth HBM memory, and open interconnect technologies. AMD positioned Helios for large-scale AI training workloads where memory constraints often become a bottleneck. Su said AMD’s strategy prioritizes openness, allowing customers to expand and customize AI infrastructure without being locked into proprietary architectures. AMD plans to deploy Helios later this year through partnerships with data center operators and enterprise customers, underscoring its push to establish itself as a core platform provider in the AI ecosystem. 2026-01-06 15:06:10 -

![[CES 2026] NVIDIA CEO unveils Vera Rubin, full-stack AI platform](https://image.ajunews.com//content/image/2026/01/06/20260106104455173367_518_323.jpg) [[CES 2026]] NVIDIA CEO unveils Vera Rubin, full-stack AI platform LAS VEGAS, January 05 (AJP) -Vera Rubin - the next bar-raising AI chip platform from NVIDIA for release in the second half - is designed not as a single product, but as a full-stack platform spanning AI training, inference and deployment across large-scale systems, according to its creator Monday (local time). Unveiling the architecture, Jensen Huang, NVIDIA’s founder and chief executive, said Vera Rubin represents a shift toward platform-level computing aimed at powering end-to-end AI workloads, from model development to real-world deployment at scale. Clad in his signature leather jacket, Hwang introduced the newest product at a press conference held at the BlueLive Theater inside the Fontainebleau Hotel in Las Vegas, ahead of CES 2026 opening. Introducing the system as "One Platform for Every AI," Huang positioned Vera Rubin as a unified foundation designed to support AI training, inference and deployment at scale, rather than as a single chip or product line. Opening his keynote, Huang placed the launch within a broader cycle of technological change. "Every 10 to 15 years, the computer industry resets," he said, pointing to past shifts from PCs to the internet, and from cloud computing to mobile platforms. This time, he argued, the transition is more disruptive. "Two platform shifts are happening at once. Applications are being built on AI, and how we build software has fundamentally changed." Huang stressed that AI is no longer simply another layer in computing. Instead, it is reshaping the entire stack. "You no longer program software. You train it," he said. "You do not run it on CPUs. You run it on GPUs." Unlike traditional applications that rely on precompiled logic, AI systems now generate outputs dynamically, producing tokens and pixels in real time based on context and reasoning. That shift, Huang said, is driving an unprecedented surge in demand for computing power. As models grow larger and reasoning becomes central to performance, both training and inference workloads have expanded sharply. "Models are growing by an order of magnitude every year," he said, noting that test-time scaling has turned inference into a thinking process rather than a single response. "All of this is a computing problem. The faster you compute, the faster you reach the next frontier." Vera Rubin is NVIDIA’s response to that challenge. Named after astronomer Vera Florence Cooper Rubin, the platform is built through what NVIDIA calls extreme codesign, integrating six newly developed chips — including the Vera CPU and Rubin GPU — into a single system. According to NVIDIA, this approach enables large mixture-of-experts models to be trained with roughly 4x fewer GPUs and reduces inference token costs by up to 10x compared with the Blackwell platform. Huang highlighted the platform’s rack-scale architecture as a key departure from earlier designs. The Vera Rubin NVL72 system connects 72 GPUs using sixth-generation NVLink technology, creating internal bandwidth at a scale rarely seen in data centers. "The rack provides more bandwidth than the entire internet," Huang said, underscoring how data movement has become a limiting factor for modern AI systems. Memory was another issue Huang addressed directly. As AI models move toward multi-step reasoning and longer interactions, the amount of context they must retain has outgrown on-chip memory. Vera Rubin introduces a new inference context memory platform powered by BlueField-4 processors, allowing large volumes of key-value cache data to be stored and shared locally. Huang said the goal is to reduce network congestion while maintaining consistent inference performance at scale. Energy efficiency and system reliability were also emphasized. Despite significantly higher compute density, Huang said Vera Rubin systems are cooled using hot water at about 45 degrees Celsius, eliminating the need for energy-intensive chillers. The platform also introduces rack-scale confidential computing, encrypting data across CPUs, GPUs and interconnects to protect proprietary models during training and inference. Throughout the keynote, Huang repeatedly framed NVIDIA’s role as extending beyond chip design. "AI is a full stack," he said. "We are reinventing everything, from chips to infrastructure to models to applications." He added that this approach is intended to support what he described as the next phase of AI deployment, built around large-scale AI factories operated by cloud providers, enterprises and AI labs. NVIDIA said Rubin-based products will be rolled out through partners beginning in the second half of 2026, with cloud providers, AI labs and enterprise customers expected to be among the early adopters. 2026-01-06 11:23:39

[[CES 2026]] NVIDIA CEO unveils Vera Rubin, full-stack AI platform LAS VEGAS, January 05 (AJP) -Vera Rubin - the next bar-raising AI chip platform from NVIDIA for release in the second half - is designed not as a single product, but as a full-stack platform spanning AI training, inference and deployment across large-scale systems, according to its creator Monday (local time). Unveiling the architecture, Jensen Huang, NVIDIA’s founder and chief executive, said Vera Rubin represents a shift toward platform-level computing aimed at powering end-to-end AI workloads, from model development to real-world deployment at scale. Clad in his signature leather jacket, Hwang introduced the newest product at a press conference held at the BlueLive Theater inside the Fontainebleau Hotel in Las Vegas, ahead of CES 2026 opening. Introducing the system as "One Platform for Every AI," Huang positioned Vera Rubin as a unified foundation designed to support AI training, inference and deployment at scale, rather than as a single chip or product line. Opening his keynote, Huang placed the launch within a broader cycle of technological change. "Every 10 to 15 years, the computer industry resets," he said, pointing to past shifts from PCs to the internet, and from cloud computing to mobile platforms. This time, he argued, the transition is more disruptive. "Two platform shifts are happening at once. Applications are being built on AI, and how we build software has fundamentally changed." Huang stressed that AI is no longer simply another layer in computing. Instead, it is reshaping the entire stack. "You no longer program software. You train it," he said. "You do not run it on CPUs. You run it on GPUs." Unlike traditional applications that rely on precompiled logic, AI systems now generate outputs dynamically, producing tokens and pixels in real time based on context and reasoning. That shift, Huang said, is driving an unprecedented surge in demand for computing power. As models grow larger and reasoning becomes central to performance, both training and inference workloads have expanded sharply. "Models are growing by an order of magnitude every year," he said, noting that test-time scaling has turned inference into a thinking process rather than a single response. "All of this is a computing problem. The faster you compute, the faster you reach the next frontier." Vera Rubin is NVIDIA’s response to that challenge. Named after astronomer Vera Florence Cooper Rubin, the platform is built through what NVIDIA calls extreme codesign, integrating six newly developed chips — including the Vera CPU and Rubin GPU — into a single system. According to NVIDIA, this approach enables large mixture-of-experts models to be trained with roughly 4x fewer GPUs and reduces inference token costs by up to 10x compared with the Blackwell platform. Huang highlighted the platform’s rack-scale architecture as a key departure from earlier designs. The Vera Rubin NVL72 system connects 72 GPUs using sixth-generation NVLink technology, creating internal bandwidth at a scale rarely seen in data centers. "The rack provides more bandwidth than the entire internet," Huang said, underscoring how data movement has become a limiting factor for modern AI systems. Memory was another issue Huang addressed directly. As AI models move toward multi-step reasoning and longer interactions, the amount of context they must retain has outgrown on-chip memory. Vera Rubin introduces a new inference context memory platform powered by BlueField-4 processors, allowing large volumes of key-value cache data to be stored and shared locally. Huang said the goal is to reduce network congestion while maintaining consistent inference performance at scale. Energy efficiency and system reliability were also emphasized. Despite significantly higher compute density, Huang said Vera Rubin systems are cooled using hot water at about 45 degrees Celsius, eliminating the need for energy-intensive chillers. The platform also introduces rack-scale confidential computing, encrypting data across CPUs, GPUs and interconnects to protect proprietary models during training and inference. Throughout the keynote, Huang repeatedly framed NVIDIA’s role as extending beyond chip design. "AI is a full stack," he said. "We are reinventing everything, from chips to infrastructure to models to applications." He added that this approach is intended to support what he described as the next phase of AI deployment, built around large-scale AI factories operated by cloud providers, enterprises and AI labs. NVIDIA said Rubin-based products will be rolled out through partners beginning in the second half of 2026, with cloud providers, AI labs and enterprise customers expected to be among the early adopters. 2026-01-06 11:23:39 -

![[CES 2026] NVIDIA CEO Jensen Huang delivers keynote speech](https://image.ajunews.com//content/image/2026/01/06/20260106105551777607_518_323.jpg) [[CES 2026]] NVIDIA CEO Jensen Huang delivers keynote speech Las Vegas, January 5 (AJP) - NVIDIA CEO Jensen Huang delivered the keynote address during an NVIDIA press conference at the Fontainebleau Hotel's BlueLive Theater in Las Vegas on Monday (local time). 2026-01-06 11:09:34

[[CES 2026]] NVIDIA CEO Jensen Huang delivers keynote speech Las Vegas, January 5 (AJP) - NVIDIA CEO Jensen Huang delivered the keynote address during an NVIDIA press conference at the Fontainebleau Hotel's BlueLive Theater in Las Vegas on Monday (local time). 2026-01-06 11:09:34 -

![[CES 2026] China accelerates robotics push as Korea takes platform-focused approach](https://image.ajunews.com//content/image/2026/01/05/20260105122118577491_518_323.jpg) [[CES 2026]] China accelerates robotics push as Korea takes platform-focused approach LAS VEGAS, January 04 (AJP) - As the world’s largest technology exhibition CES 2026 opens on Jan. 6 in Las Vegas, competition around robotics and physical AI is expected to intensify. With artificial intelligence expanding beyond software into hardware, robotics has moved to the center of the show’s technology landscape, and Chinese companies are set to play a more visible role this year. According to the Korea Information and Communication Technology Association (KICTA), about 4,300 companies are participating in CES 2026. Of these, 942 are Chinese firms, accounting for roughly 22 percent of all exhibitors, the second-largest national presence after the United States. South Korea ranks third with 853 participating companies. While the overall numbers remain close, attention is increasingly shifting toward how heavily companies are concentrating on robotics-related exhibits. Chinese firms make up 149 of the 598 exhibitors participating in the robotics category, representing nearly one quarter of the total. Their displays span humanoid robots, embodied robots, and hybrid models that combine bipedal and wheeled mobility. Many Chinese companies are presenting products intended for commercialization rather than concept demonstrations, placing emphasis on practical deployment and near-term use cases. This momentum is closely tied to China’s industrial policy direction. The Chinese government has designated 2025 as the first year of humanoid robot commercialization and has supported the sector through national roadmaps, large-scale investment funds, tax incentives, and policy-based financial programs. CES 2026 provides a venue where these efforts are reflected through product launches and live demonstrations. Interest is also building around individual Chinese robotics companies participating in the show. CES 2026 features firms such as UBTECH and Fourier Intelligence, alongside Unitree, which has gained attention for advancing both quadruped and humanoid robots toward commercialization. Unitree has focused on relatively lower pricing and rapid development cycles, expanding its presence in research and industrial markets overseas. The company is expected to conduct live demonstrations during the exhibition. South Korean companies are approaching the robotics competition from a different angle. Although their overall participation level is comparable to China’s, fewer domestic firms are emphasizing complete robot hardware systems. Instead, strengths are concentrated in AI software, sensors, semiconductors, and key components. While many South Korean companies have received CES Innovation Awards, their robotics presence reflects a more selective and targeted focus. Among major exhibitors, Samsung Electronics is taking a measured approach. Rather than competing through large-scale public demonstrations, the company plans to engage clients and partners through private exhibitions, presenting an integrated technology stack spanning AI data centers, on-device AI, and physical AI. The emphasis is placed on platforms and ecosystems rather than individual robot products. 2026-01-05 12:59:54

[[CES 2026]] China accelerates robotics push as Korea takes platform-focused approach LAS VEGAS, January 04 (AJP) - As the world’s largest technology exhibition CES 2026 opens on Jan. 6 in Las Vegas, competition around robotics and physical AI is expected to intensify. With artificial intelligence expanding beyond software into hardware, robotics has moved to the center of the show’s technology landscape, and Chinese companies are set to play a more visible role this year. According to the Korea Information and Communication Technology Association (KICTA), about 4,300 companies are participating in CES 2026. Of these, 942 are Chinese firms, accounting for roughly 22 percent of all exhibitors, the second-largest national presence after the United States. South Korea ranks third with 853 participating companies. While the overall numbers remain close, attention is increasingly shifting toward how heavily companies are concentrating on robotics-related exhibits. Chinese firms make up 149 of the 598 exhibitors participating in the robotics category, representing nearly one quarter of the total. Their displays span humanoid robots, embodied robots, and hybrid models that combine bipedal and wheeled mobility. Many Chinese companies are presenting products intended for commercialization rather than concept demonstrations, placing emphasis on practical deployment and near-term use cases. This momentum is closely tied to China’s industrial policy direction. The Chinese government has designated 2025 as the first year of humanoid robot commercialization and has supported the sector through national roadmaps, large-scale investment funds, tax incentives, and policy-based financial programs. CES 2026 provides a venue where these efforts are reflected through product launches and live demonstrations. Interest is also building around individual Chinese robotics companies participating in the show. CES 2026 features firms such as UBTECH and Fourier Intelligence, alongside Unitree, which has gained attention for advancing both quadruped and humanoid robots toward commercialization. Unitree has focused on relatively lower pricing and rapid development cycles, expanding its presence in research and industrial markets overseas. The company is expected to conduct live demonstrations during the exhibition. South Korean companies are approaching the robotics competition from a different angle. Although their overall participation level is comparable to China’s, fewer domestic firms are emphasizing complete robot hardware systems. Instead, strengths are concentrated in AI software, sensors, semiconductors, and key components. While many South Korean companies have received CES Innovation Awards, their robotics presence reflects a more selective and targeted focus. Among major exhibitors, Samsung Electronics is taking a measured approach. Rather than competing through large-scale public demonstrations, the company plans to engage clients and partners through private exhibitions, presenting an integrated technology stack spanning AI data centers, on-device AI, and physical AI. The emphasis is placed on platforms and ecosystems rather than individual robot products. 2026-01-05 12:59:54 -

KAIST researchers develop brain-like AI chip perceiving and thinking instantly SEOUL, December 31 (AJP) - Researchers at the Korea Advanced Institute of Science and Technology have developed a next-generation artificial intelligence semiconductor that integrates sensing, computing, and memory into a single chip. By mimicking the structure of the human eye and brain, the technology allows devices to perceive and process information instantly without the power loss or delays found in traditional computers. The Korea Advanced Institute of Science and Technology (KAIST) announced on December 31, Wednesday, that a research team led by Professor Chon Sang-hun from the School of Electrical Engineering presented six papers at the International Electron Devices Meeting (IEEE IEDM 2025) in San Francisco. The team work on integrated vision sensors was selected as a "Highlight Paper," and their research on highly reliable memory received the "Top Ranked Student Paper" award. Standard AI systems function like a relay race: a camera sensor takes a picture, converts it into numbers, moves those numbers to memory for storage, and then sends them to a processor to be calculated. This constant moving of data back and forth uses a lot of electricity and creates a "lag" in response time. The KAIST team solved this by creating a "full-stack" AI chip where the sensor and the brain-like processing circuits are physically stacked on top of each other in very thin layers. This "in-sensor" technology allows the chip to "see and think" at the same time. Instead of sending raw data elsewhere, the sensor itself performs the calculations. This mimics how the human nervous system processes basic visual features before the information even reaches the deep brain. By eliminating the need to move data between different chips, the system uses significantly less power and reacts much faster, making it ideal for real-time use in mobile devices, drones, and robots. In addition to the sensing technology, the team improved the storage part of the AI chip. They developed a new type of memory called "Next-Generation NAND Flash" that uses a special material to store data more reliably while using lower voltage. This ensures that the AI can store vast amounts of information safely for a long time without draining the battery. Professor Chon Sang-hun stated that this research proves that sensors, computation, and storage—which used to be designed separately—can be combined into one single system and material. He noted that this platform will be expanded for use in "edge AI," which refers to smart devices that need to process complex information locally and instantly without relying on a central server. The research was supported by the Ministry of Science and ICT and the National Research Foundation of Korea. It was conducted in collaboration with Samsung Electronics, Kyungpook National University, and Hanyang University. (Paper information) Journal: IEEE IEDM 2025 Title: Monolithically Integrated Photodiode–Spiking Circuit for Neuromorphic Vision with In-Sensor Feature Extraction DOI: https://iedm25.mapyourshow.com/8_0/sessions/session-details.cfm?scheduleid=255 Title: A Highly Reliable Ferroelectric NAND Cell with Ultra-thin IGZO Charge Trap Layer; Trap Profile Engineering for Endurance and Retention Improvement DOI: https://iedm25.mapyourshow.com/8_0/sessions/session-details.cfm?scheduleid=124 2025-12-31 13:46:54

KAIST researchers develop brain-like AI chip perceiving and thinking instantly SEOUL, December 31 (AJP) - Researchers at the Korea Advanced Institute of Science and Technology have developed a next-generation artificial intelligence semiconductor that integrates sensing, computing, and memory into a single chip. By mimicking the structure of the human eye and brain, the technology allows devices to perceive and process information instantly without the power loss or delays found in traditional computers. The Korea Advanced Institute of Science and Technology (KAIST) announced on December 31, Wednesday, that a research team led by Professor Chon Sang-hun from the School of Electrical Engineering presented six papers at the International Electron Devices Meeting (IEEE IEDM 2025) in San Francisco. The team work on integrated vision sensors was selected as a "Highlight Paper," and their research on highly reliable memory received the "Top Ranked Student Paper" award. Standard AI systems function like a relay race: a camera sensor takes a picture, converts it into numbers, moves those numbers to memory for storage, and then sends them to a processor to be calculated. This constant moving of data back and forth uses a lot of electricity and creates a "lag" in response time. The KAIST team solved this by creating a "full-stack" AI chip where the sensor and the brain-like processing circuits are physically stacked on top of each other in very thin layers. This "in-sensor" technology allows the chip to "see and think" at the same time. Instead of sending raw data elsewhere, the sensor itself performs the calculations. This mimics how the human nervous system processes basic visual features before the information even reaches the deep brain. By eliminating the need to move data between different chips, the system uses significantly less power and reacts much faster, making it ideal for real-time use in mobile devices, drones, and robots. In addition to the sensing technology, the team improved the storage part of the AI chip. They developed a new type of memory called "Next-Generation NAND Flash" that uses a special material to store data more reliably while using lower voltage. This ensures that the AI can store vast amounts of information safely for a long time without draining the battery. Professor Chon Sang-hun stated that this research proves that sensors, computation, and storage—which used to be designed separately—can be combined into one single system and material. He noted that this platform will be expanded for use in "edge AI," which refers to smart devices that need to process complex information locally and instantly without relying on a central server. The research was supported by the Ministry of Science and ICT and the National Research Foundation of Korea. It was conducted in collaboration with Samsung Electronics, Kyungpook National University, and Hanyang University. (Paper information) Journal: IEEE IEDM 2025 Title: Monolithically Integrated Photodiode–Spiking Circuit for Neuromorphic Vision with In-Sensor Feature Extraction DOI: https://iedm25.mapyourshow.com/8_0/sessions/session-details.cfm?scheduleid=255 Title: A Highly Reliable Ferroelectric NAND Cell with Ultra-thin IGZO Charge Trap Layer; Trap Profile Engineering for Endurance and Retention Improvement DOI: https://iedm25.mapyourshow.com/8_0/sessions/session-details.cfm?scheduleid=124 2025-12-31 13:46:54 -

Samsung Electronics begins manufacturing operations in Kazakhstan SEOUL, December 31 (AJP) - Samsung Electronics has officially launched the production of televisions and washing machines in Kazakhstan, marking the South Korean tech giant's first manufacturing presence in the Central Asian nation. The Embassy of Kazakhstan in South Korea said Wednesday that the new production lines are operating at the Silk Road Electronics plant in Saran, a city in the Karaganda Region. The facility currently employs more than 1,100 people. The project is a joint initiative involving the Kazakh government, private investors, and industry partners designed to expand the country's domestic machine-building capabilities. According to the embassy, the plant has an annual production capacity of 150,000 televisions and 200,000 washing machines. It is currently producing washing machines that support the SmartThings ecosystem, as well as Crystal UHD 4K, FHD, and HD television models. Since mass production began earlier this year, the facility has turned out more than 42,000 units. These include models featuring artificial intelligence technology and user interfaces localized in the Kazakh language. Officials plan to add QLED TV series to the production lines in the future. The plant has also started manufacturing 2026 model-year televisions, which the embassy noted meets Samsung's international production standards. 2025-12-31 13:35:25

Samsung Electronics begins manufacturing operations in Kazakhstan SEOUL, December 31 (AJP) - Samsung Electronics has officially launched the production of televisions and washing machines in Kazakhstan, marking the South Korean tech giant's first manufacturing presence in the Central Asian nation. The Embassy of Kazakhstan in South Korea said Wednesday that the new production lines are operating at the Silk Road Electronics plant in Saran, a city in the Karaganda Region. The facility currently employs more than 1,100 people. The project is a joint initiative involving the Kazakh government, private investors, and industry partners designed to expand the country's domestic machine-building capabilities. According to the embassy, the plant has an annual production capacity of 150,000 televisions and 200,000 washing machines. It is currently producing washing machines that support the SmartThings ecosystem, as well as Crystal UHD 4K, FHD, and HD television models. Since mass production began earlier this year, the facility has turned out more than 42,000 units. These include models featuring artificial intelligence technology and user interfaces localized in the Kazakh language. Officials plan to add QLED TV series to the production lines in the future. The plant has also started manufacturing 2026 model-year televisions, which the embassy noted meets Samsung's international production standards. 2025-12-31 13:35:25 -

KAIST researchers wake up sleeping immune cells to attack cancer SEOUL, December 30 (AJP) - Scientists at the Korea Advanced Institute of Science and Technology have developed a way to turn a patient's own "sleeping" immune cells into cancer-killing machines. Instead of expensive and complicated laboratory processes, the new treatment works by injecting a special medicine directly into a tumor to reprogram cells from the inside. The Korea Advanced Institute of Science and Technology (KAIST) announced on December 30 that a research team led by Professor Park Ji-ho from the Department of Bio and Brain Engineering has created an "in-situ" cell therapy. This method turns local immune cells into "CAR-macrophages," which are advanced cells genetically programmed to hunt and eat cancer. Solid tumors, such as those found in the liver, lungs, or stomach, are very hard to treat because they act like fortresses. They are physically tough to enter and use chemical signals to put nearby immune cells to sleep. Current "CAR" therapies usually require doctors to take blood out of a patient, change the cells in a lab for weeks, and then put them back in. This is very expensive, and often the new cells cannot even get inside the tough tumor fortress once they are returned to the body. The KAIST team decided to use the cells that are already inside the tumor. They created tiny lipid nanoparticles—microscopic bubbles—that contain a set of instructions called mRNA and a chemical alarm. The mRNA tells the cell how to build a "cancer-seeking radar," while the alarm wakes the cell up and makes it aggressive toward the cancer. When this mixture is injected into the tumor, the resident immune cells swallow the bubbles and read the instructions. They immediately begin building the radar and start attacking the tumor from the inside out. In tests on animals with melanoma, a dangerous skin cancer, the treatment stopped tumors from growing. Because the "radar" cells were created right where they were needed, they were much more effective than laboratory-made versions. The researchers also found that once these cells were "awake," they sent out signals to the rest of the body's immune system, helping it fight cancer everywhere, not just where the injection happened. Professor Park Ji-ho stated that this is a new way to make the body create its own medicine. He noted that it solves the biggest problems of current treatments, specifically how to get the medicine into the tumor and how to keep it working once it is there. The study, with Han Jun-hee as the lead author, was published in the journal ACS Nano. (Paper information) Journal: ACS Nano Title: In Situ Chimeric Antigen Receptor Macrophage Therapy via Co-Delivery of mRNA and Immunostimulant DOI: https://doi.org/10.1021/acsnano.5c09138 2025-12-30 10:55:20

KAIST researchers wake up sleeping immune cells to attack cancer SEOUL, December 30 (AJP) - Scientists at the Korea Advanced Institute of Science and Technology have developed a way to turn a patient's own "sleeping" immune cells into cancer-killing machines. Instead of expensive and complicated laboratory processes, the new treatment works by injecting a special medicine directly into a tumor to reprogram cells from the inside. The Korea Advanced Institute of Science and Technology (KAIST) announced on December 30 that a research team led by Professor Park Ji-ho from the Department of Bio and Brain Engineering has created an "in-situ" cell therapy. This method turns local immune cells into "CAR-macrophages," which are advanced cells genetically programmed to hunt and eat cancer. Solid tumors, such as those found in the liver, lungs, or stomach, are very hard to treat because they act like fortresses. They are physically tough to enter and use chemical signals to put nearby immune cells to sleep. Current "CAR" therapies usually require doctors to take blood out of a patient, change the cells in a lab for weeks, and then put them back in. This is very expensive, and often the new cells cannot even get inside the tough tumor fortress once they are returned to the body. The KAIST team decided to use the cells that are already inside the tumor. They created tiny lipid nanoparticles—microscopic bubbles—that contain a set of instructions called mRNA and a chemical alarm. The mRNA tells the cell how to build a "cancer-seeking radar," while the alarm wakes the cell up and makes it aggressive toward the cancer. When this mixture is injected into the tumor, the resident immune cells swallow the bubbles and read the instructions. They immediately begin building the radar and start attacking the tumor from the inside out. In tests on animals with melanoma, a dangerous skin cancer, the treatment stopped tumors from growing. Because the "radar" cells were created right where they were needed, they were much more effective than laboratory-made versions. The researchers also found that once these cells were "awake," they sent out signals to the rest of the body's immune system, helping it fight cancer everywhere, not just where the injection happened. Professor Park Ji-ho stated that this is a new way to make the body create its own medicine. He noted that it solves the biggest problems of current treatments, specifically how to get the medicine into the tumor and how to keep it working once it is there. The study, with Han Jun-hee as the lead author, was published in the journal ACS Nano. (Paper information) Journal: ACS Nano Title: In Situ Chimeric Antigen Receptor Macrophage Therapy via Co-Delivery of mRNA and Immunostimulant DOI: https://doi.org/10.1021/acsnano.5c09138 2025-12-30 10:55:20 -

KAIST team develops one-second powder to stop battlefield bleeding SEOUL, December 29 (AJP) - Researchers at the Korea Advanced Institute of Science and Technology have developed a powder-based hemostatic agent that can stop heavy bleeding within approximately one second of contact. The technology is designed to improve the survival rates of soldiers in combat environments where excessive blood loss is the leading cause of death. The Korea Advanced Institute of Science and Technology (KAIST) announced on December 29 that a joint research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jeon Sang-yong from the Department of Biological Sciences created the material. The project included the participation of an active-duty South Korean Army major to ensure the technology meets the practical demands of the battlefield. Traditional hemostatic agents often come in the form of patches, which are difficult to apply to deep or irregularly shaped wounds. These patches can also lose effectiveness in high-temperature or humid environments. To overcome these limitations, the KAIST team developed a powder that can be sprinkled directly into any wound shape, instantly forming a strong physical barrier. The new material, named AGCL powder, is made from natural substances including alginate, gellan gum, and chitosan. When the powder touches blood, it reacts with calcium ions naturally present in the body. This reaction causes the powder to turn into a solid hydrogel in about one second, sealing the wound. Chitosan further strengthens this seal by binding with blood components. The AGCL powder can absorb blood weighing more than seven times its own weight. In testing, it demonstrated a sealing pressure of over 40 kilopascals, which is strong enough to withstand heavy, high-pressure bleeding even when external pressure is applied by hand. This performance significantly exceeds that of existing commercial products. Animal testing showed that the powder is safe and promotes healing. It resulted in a hemolysis rate of less than 3 percent and a cell survival rate of over 99 percent, while also providing 99.9 percent antibacterial protection. In liver surgery experiments, the powder reduced blood loss and shortened bleeding time compared to current medical products, with liver functions returning to normal within two weeks. The powder remains stable for two years even when stored at room temperature in high humidity. This durability makes it suitable for use in combat zones, disaster areas, or regions with limited medical infrastructure. While developed for military use, the researchers noted the technology can be applied to civilian emergency medicine and surgical procedures. "The core of modern warfare is minimizing the loss of life," said Park Kyu-soon, a doctoral student at KAIST and a major in the South Korean Army who served as the first author of the study. "I started this research with a sense of mission to save even one more soldier. I hope this technology will be used to save lives in both national defense and civilian medical fields." The research was supported by KAIST and received the Minister of National Defense Award at the 2024 KAIST-KNDU Defense Academic Conference. (Paper information) Journal: Advanced Functional Materials (impact factor 19.0) Title: An Ionic Gelation Powder for Ultrafast Hemostasis and Accelerated Wound Healing DOI: https://doi.org/10.1002/adfm.202523910 2025-12-29 10:35:34

KAIST team develops one-second powder to stop battlefield bleeding SEOUL, December 29 (AJP) - Researchers at the Korea Advanced Institute of Science and Technology have developed a powder-based hemostatic agent that can stop heavy bleeding within approximately one second of contact. The technology is designed to improve the survival rates of soldiers in combat environments where excessive blood loss is the leading cause of death. The Korea Advanced Institute of Science and Technology (KAIST) announced on December 29 that a joint research team led by Professor Steve Park from the Department of Materials Science and Engineering and Professor Jeon Sang-yong from the Department of Biological Sciences created the material. The project included the participation of an active-duty South Korean Army major to ensure the technology meets the practical demands of the battlefield. Traditional hemostatic agents often come in the form of patches, which are difficult to apply to deep or irregularly shaped wounds. These patches can also lose effectiveness in high-temperature or humid environments. To overcome these limitations, the KAIST team developed a powder that can be sprinkled directly into any wound shape, instantly forming a strong physical barrier. The new material, named AGCL powder, is made from natural substances including alginate, gellan gum, and chitosan. When the powder touches blood, it reacts with calcium ions naturally present in the body. This reaction causes the powder to turn into a solid hydrogel in about one second, sealing the wound. Chitosan further strengthens this seal by binding with blood components. The AGCL powder can absorb blood weighing more than seven times its own weight. In testing, it demonstrated a sealing pressure of over 40 kilopascals, which is strong enough to withstand heavy, high-pressure bleeding even when external pressure is applied by hand. This performance significantly exceeds that of existing commercial products. Animal testing showed that the powder is safe and promotes healing. It resulted in a hemolysis rate of less than 3 percent and a cell survival rate of over 99 percent, while also providing 99.9 percent antibacterial protection. In liver surgery experiments, the powder reduced blood loss and shortened bleeding time compared to current medical products, with liver functions returning to normal within two weeks. The powder remains stable for two years even when stored at room temperature in high humidity. This durability makes it suitable for use in combat zones, disaster areas, or regions with limited medical infrastructure. While developed for military use, the researchers noted the technology can be applied to civilian emergency medicine and surgical procedures. "The core of modern warfare is minimizing the loss of life," said Park Kyu-soon, a doctoral student at KAIST and a major in the South Korean Army who served as the first author of the study. "I started this research with a sense of mission to save even one more soldier. I hope this technology will be used to save lives in both national defense and civilian medical fields." The research was supported by KAIST and received the Minister of National Defense Award at the 2024 KAIST-KNDU Defense Academic Conference. (Paper information) Journal: Advanced Functional Materials (impact factor 19.0) Title: An Ionic Gelation Powder for Ultrafast Hemostasis and Accelerated Wound Healing DOI: https://doi.org/10.1002/adfm.202523910 2025-12-29 10:35:34