SEOUL, February 22 (AJP) -Hyundai Motor Group said Sunday it will invest a record 125.2 trillion won ($93 billion) in South Korea from 2026 to 2030 under a more aggressive and detailed robotics and physical artificial intelligence roadmap unveiled last month after the high-profile debut of its industrial and humanoid robot lineup at a major global technology exhibition.

The five-year domestic investment plan marks the largest in the group’s history and reflects Hyundai’s ambition to position itself as a global hub for next-generation manufacturing and intelligent mobility.

Of the total, 71.1 percent — about 89 trillion won — will be allocated to future industries and research and development, including robotics, AI, electric vehicles, hydrogen and software-defined vehicles (SDVs).

Hyundai said these technologies form an integrated growth platform centered on physical AI, which combines robotics hardware, real-world data and advanced software.

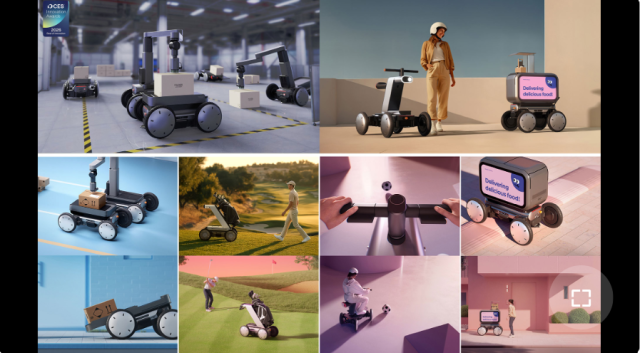

Rather than limiting its focus to robot manufacturing, Hyundai aims to establish a comprehensive value chain spanning contract production, subscription services, training hubs, AI learning systems and real-time control platforms.

Group officials said competitiveness in robotics will hinge less on raw performance and more on how effectively robots are deployed and improved through continuous field data.

Hyundai plans to leverage massive datasets generated across its affiliates — from automobiles and steelmaking to parts, logistics, defense and rail — to accelerate AI learning and commercialization.

“Without real-world operational data, even advanced robots cannot evolve into competitive products,” the group said.

By 2028, Hyundai aims to build annual production capacity for 30,000 robots, securing an early foothold in the fast-growing global market.

The facility would serve as a large-scale training and validation base for humanoid and industrial robots.

At the same time, the group is considering building AI data centers along Korea’s southwestern coast, including South Jeolla and North Jeolla provinces, where renewable energy can support high-intensity computing and data storage.

Hyundai is pursuing a dual-track strategy that combines in-house hardware development with external software partnerships.

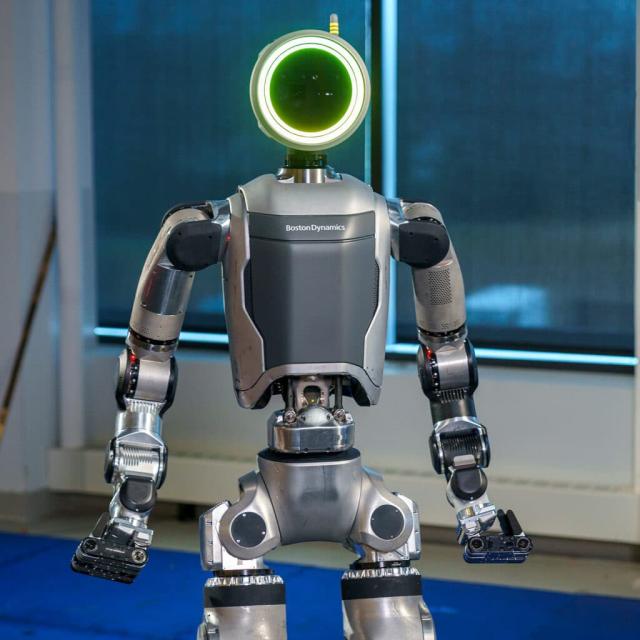

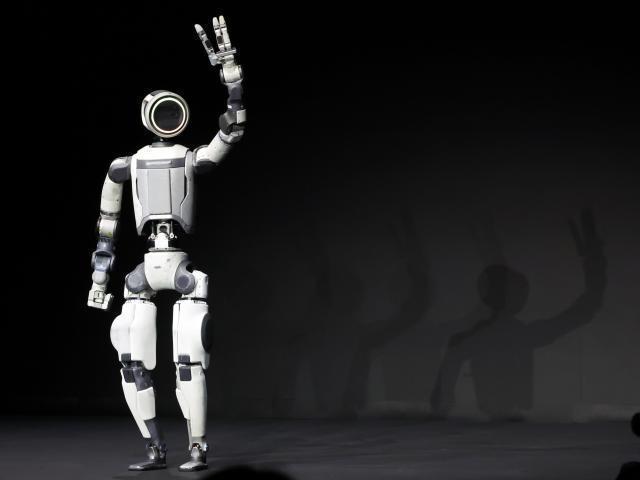

Through its U.S. robotics subsidiary Boston Dynamics, the group produces advanced robots such as the humanoid Atlas and quadruped Spot. Hyundai Mobis supplies core actuators and modules, Hyundai AutoEver operates robot control systems, and Hyundai Glovis manages logistics and distribution.

Under the roadmap, Hyundai recently invested several million dollars in U.S.-based startup Field AI, which develops foundation models enabling robots to navigate unfamiliar environments without prebuilt maps.

Field AI’s technology has already been tested on Spot robots at construction sites and is expected to be applied to next-generation Atlas models, potentially strengthening Hyundai’s plan to deploy humanoids at its U.S. plant from 2028.

Hyundai has also secured 50,000 of the latest Blackwell processors from Nvidia to reinforce its AI computing infrastructure.

The long-term robotics drive comes as Hyundai Motor Company has begun accelerating spending under its five-year capital framework.

The automaker said last month it will invest 17.8 trillion won in 2026 alone — more than it earned in 2025 — focusing on robotics, autonomous driving and hydrogen technology. The amount accounts for about 23 percent of its previously announced 77.3 trillion won investment plan for 2026–2030.

“We plan to concentrate investment in 2026 and 2027,” said Lee Seung-jo, chief financial officer of Hyundai Motor, during an earnings call.

“Spending will peak during this period, though the overall investment envelope remains unchanged,” he said.

Analysts say the front-loaded strategy reflects Hyundai’s determination to secure early leadership in physical AI and humanoid robotics, as global rivals move rapidly toward commercialization.

Hyundai’s robotics push is closely tied to autonomous driving and SDVs, as both rely on similar algorithms for perception, route planning and real-time decision-making.

Park Min Woo, head of the group’s Advanced Vehicle Platform division and CEO of 42dot, is expected to play a central role in integrating robotics and vehicle software. A former executive at Tesla and Nvidia, Park is tasked with accelerating Hyundai’s transition toward a unified mobility ecosystem.

Hyundai said South Korea is well-positioned to emerge as a global robotics hub under its “DESIGN” framework — demand, experience, supply chain, infrastructure, government and network.

The group cited demographic pressures, estimating that Korea will need 1.22 million additional workers by 2034 due to low birth rates and rapid aging, creating structural demand for automation.

Korea’s manufacturing robot density — 1,012 units per 10,000 workers in 2023 — far exceeds second-place Singapore, reflecting strong operational experience. Dense supplier networks, high-speed communications and cloud infrastructure further support large-scale AI learning and robot control, Hyundai said.

"The target is to complete an intelligent factory where robots can operate autonomously in dynamic environments,” the official said.

Copyright ⓒ Aju Press All rights reserved.